Formidable Info About How To Check Bolt Tightness

Why Bolt Tightness Matters (and Why You Should Care)

1. The Secret Life of Bolts

Okay, let's be honest. Bolts. They don't exactly scream excitement, do they? But think about it: they're the unsung heroes holding our world together! From bridges and buildings to cars and coffee makers, bolts are quietly doing their job. But a loose bolt? That's a recipe for disaster. It can lead to wobbly structures, noisy machinery, and, in extreme cases, catastrophic failures. So, showing those little guys some love and making sure they're properly tightened is more important than you might think.

Imagine a wobbly ceiling fan. Annoying, right? That's probably a loose bolt. Or picture a critical joint in a car's suspension coming undone at 70 mph. Suddenly, bolt tightness becomes a life-or-death matter. Regularly checking bolt tightness is preventative maintenance at its finest — a little effort now can save you a whole lot of trouble (and money!) later.

But it's not just about avoiding disasters. Properly tightened bolts also improve the performance and lifespan of whatever they're holding together. Tight bolts distribute stress evenly, preventing premature wear and tear. Think of it like a team effort; when everyone's pulling their weight, the job gets done right. And when bolts aren't pulling their weight? Well, things start to fall apart.

So, before you dismiss bolt tightness as a boring technicality, consider the vital role these little fasteners play in our daily lives. A little attention to detail can make a world of difference. Plus, you get to feel like a mechanical genius, which is always a bonus.

Calculate Strength

Different Ways to Check Bolt Tightness

2. The Torque Wrench Tango

The gold standard for checking bolt tightness? The torque wrench. This tool measures the amount of rotational force applied to a bolt, ensuring it meets the manufacturer's specifications. Think of it as a sophisticated handshake that confirms the bolt is holding on tight enough, but not too tight. Over-tightening can strip threads or stretch the bolt, rendering it useless.

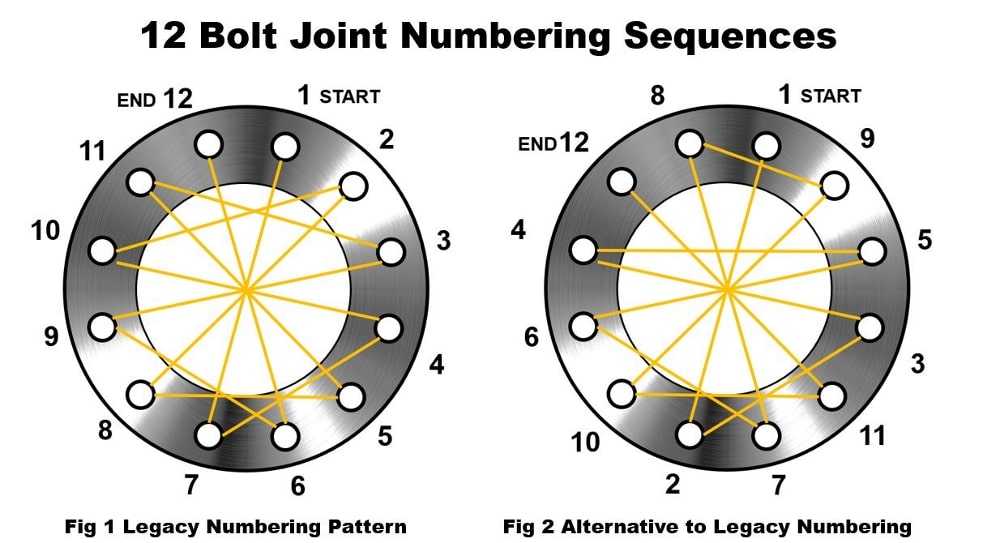

Using a torque wrench is relatively straightforward. First, find the recommended torque value for the specific bolt (usually found in the equipment's manual). Set the torque wrench to that value. Then, carefully tighten the bolt until the wrench clicks or beeps (depending on the model), indicating that the desired torque has been reached. Remember, precision is key here. Don't just guess — use the right tool for the job.

There are different types of torque wrenches available, including click-type, beam-type, and digital models. Click-type wrenches are the most common and user-friendly, providing a distinct "click" when the target torque is reached. Beam-type wrenches are simpler and more affordable, but require a bit more skill to use accurately. Digital torque wrenches offer the highest level of precision and often feature memory functions and data logging capabilities. It's all about choosing the right dance partner for the torque tango!

One crucial tip: always store your torque wrench at its lowest setting when not in use. This helps to preserve its calibration and ensure accurate readings for years to come. A well-maintained torque wrench is an investment in safety and peace of mind.

Less Precise, But Still Useful Methods

3. The "Feel" Method (Use with Caution!)

Alright, let's be real. Not everyone has a torque wrench lying around. So, what if you need to check bolt tightness in a pinch? The "feel" method involves using your experience and judgment to assess whether a bolt is properly tightened. This method relies on years of experience and should only be used in scenarios where accuracy is not paramount. It's more art than science, and definitely not recommended for critical applications. Imagine trying to paint the Mona Lisa with a house painting brush.

To attempt the feel method, start by trying to tighten the bolt slightly with a standard wrench. If it moves easily, it's probably loose. If it requires significant effort to turn, it's likely tight enough. The key is to develop a sense of how much force is required to tighten a bolt of a given size and type. This comes with practice and familiarity with different types of fasteners.

However, be warned: the feel method is highly subjective and prone to error. It's easy to over-tighten or under-tighten a bolt, especially if you're not experienced. Over-tightening can damage the bolt or the threads, while under-tightening can lead to loosening and failure. Use this method at your own risk!

Consider this analogy: it's like trying to bake a cake without measuring ingredients. You might get lucky and end up with something edible, but the odds are stacked against you. For critical applications, always use a torque wrench to ensure accuracy and safety. The "feel" method is more of a last resort than a reliable technique.

Bolted Joint

Visual Inspection

4. The Eyes Have It

Sometimes, you don't even need a wrench to tell if a bolt is loose. A simple visual inspection can reveal telltale signs of trouble. Look for things like rust streaks around the bolt head, which indicate that the bolt is moving and allowing moisture to seep in. Or check for gaps between the bolt head and the surface it's clamping together. A gap is a clear sign that the bolt is not properly tightened.

Also, pay attention to the overall condition of the bolt. Are the threads damaged or corroded? Is the bolt head rounded off? These are all signs that the bolt may be compromised and needs to be replaced. A worn-out bolt is like a weak link in a chain; it can break under stress and cause a failure.

Another important thing to look for is evidence of vibration. Vibration can cause bolts to loosen over time, especially in machinery or vehicles. If you notice excessive vibration, it's a good idea to check the tightness of all the bolts in the area. Think of it like a constant earthquake slowly weakening the foundations of a building.

Regular visual inspections are a quick and easy way to catch potential problems before they escalate. It's like checking the oil in your car; a little preventive maintenance can save you a lot of headaches down the road. So, take a few minutes to visually inspect your bolts from time to time — your eyes will thank you for it.

Prevention is Better Than Cure

5. Bolt Hygiene & the Power of Prevention

The best way to deal with loose bolts is to prevent them from loosening in the first place. There are several simple steps you can take to keep your bolts tight and secure. One of the most effective is to use locking fasteners, such as lock washers, lock nuts, or thread-locking compounds (like Loctite). These devices create friction or a chemical bond that prevents the bolt from backing out.

Another important factor is proper bolt selection. Make sure you're using the right type and size of bolt for the application. Using the wrong bolt can lead to premature failure. Its like trying to use a butter knife to chop wood; it's just not the right tool for the job.

Also, remember to clean and lubricate the threads before tightening the bolt. This helps to reduce friction and ensure accurate torque readings. A little bit of lubricant can go a long way in preventing bolt loosening. Think of it like applying moisturizer to dry skin; it keeps things smooth and supple.

Finally, establish a regular maintenance schedule for checking bolt tightness. How often you need to check depends on the application and the operating environment. In high-vibration environments, you may need to check bolt tightness more frequently. Regular maintenance is like brushing your teeth; it's a simple habit that can prevent serious problems down the road. So, make bolt tightness checks a part of your routine, and you'll be well on your way to preventing loose bolt disasters.

Bolt Hardness Markings

FAQ

6. Your Burning Bolt Questions Answered

Still scratching your head about bolt tightness? Here are some frequently asked questions to clear things up:

Q: How often should I check bolt tightness?

A: It depends! For critical applications like car suspensions or machinery, check monthly or even weekly. For less critical applications, a visual inspection every few months might suffice. High-vibration environments require more frequent checks.Q: What happens if I overtighten a bolt?

A: Overtightening can strip the threads or stretch the bolt, weakening it and potentially causing it to break. Always use a torque wrench to avoid overtightening.Q: Can I reuse old bolts?

A: It depends on the application and the condition of the bolt. If the bolt is damaged, corroded, or has been subjected to excessive stress, it's best to replace it. For critical applications, always use new bolts.Q: What's the best way to loosen a stuck bolt?

A: Penetrating oil is your friend! Apply it to the threads and let it soak in for a while. You can also try tapping the bolt head with a hammer to help loosen it. If all else fails, heat can sometimes help to break the bond.