Unique Info About How Do You Reduce Leakage In A MOSFET

Nanoscale MOSFET’s Leakage Current Components, Which Are Bias Dependent

Understanding MOSFET Leakage

1. The Silent Energy Thief

So, you're wrestling with MOSFET leakage, huh? Don't worry, you're not alone. Imagine your MOSFET as a tiny gatekeeper, controlling the flow of electrons. Ideally, when the gate is "off," it should block all electrons. But in reality, a tiny trickle slips through — that's leakage. Think of it like a leaky faucet; even a small drip can waste a surprising amount of water (or, in this case, power) over time.

Why is this leakage such a big deal? Well, in battery-powered devices, every microwatt counts! That persistent leakage current drains your battery faster, leading to shorter runtimes and a potentially grumpy user (no one likes a dead phone, right?). In high-power applications, excessive leakage can even lead to overheating and reliability issues. So, tackling leakage isn't just about efficiency; it's about making sure your circuits are happy and functional.

There are a few different types of leakage current in MOSFETs, but the most common culprit is subthreshold leakage. This happens when the gate voltage is below the threshold voltage (the voltage needed to fully turn the MOSFET "on"), but still allows some current to flow. It's kind of like trying to close a door but leaving a tiny crack open. Diffusion leakage is another type of leakage current. This is related to the migration of minority carriers within the MOSFET structure due to concentration gradients, temperature, and electric fields. It's temperature-dependent, which is why leakage increases with temperature.

Ultimately, minimizing MOSFET leakage means designing circuits that are more efficient, reliable, and longer-lasting. It's a challenge, but definitely a worthwhile one. Let's dive into some strategies for reducing this pesky problem.

Figure 3 From Better Leakage Reduction By Exploiting The Builtin

Strategies for Reducing MOSFET Leakage

2. Tweaking the Design and Materials

Okay, let's get our hands dirty. How do we actually reduce this leakage? One crucial area is the MOSFET's design and the materials used in its construction. For example, using a MOSFET with a higher threshold voltage can help to reduce subthreshold leakage. This is because a higher voltage is needed to turn the MOSFET on, making it less prone to unwanted conduction when it's supposed to be off.

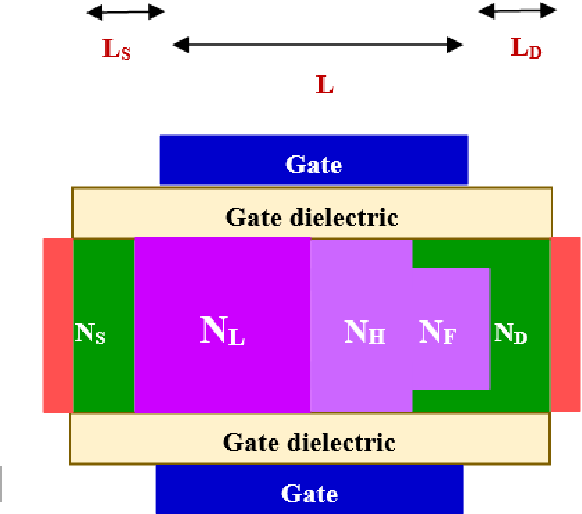

Another key consideration is the gate oxide thickness. A thicker gate oxide can reduce gate leakage current, which is another contributor to overall leakage. However, there's a trade-off here: thicker gate oxides can also slow down the switching speed of the MOSFET. So, it's all about finding the right balance for your specific application. Another important factor is the channel length of the MOSFET. Shorter channel lengths generally lead to higher leakage currents due to effects like drain-induced barrier lowering (DIBL). Increasing the channel length can help reduce leakage, but it can also increase the on-resistance of the MOSFET.

The doping profile of the MOSFET's channel also plays a role. Careful engineering of the doping profile can help to minimize subthreshold leakage and improve the MOSFET's overall performance. Techniques like halo implants can be used to create a more abrupt doping profile near the source and drain junctions, which helps to suppress leakage currents. Different materials can be used like High-k dielectrics materials. High-k dielectrics materials helps reduce gate leakage. The trade off is they can introduce other challenges, such as increased capacitance and reliability concerns.

In a nutshell, minimizing leakage requires a holistic approach that considers the MOSFET's geometry, materials, and doping profile. It's a complex optimization problem, but it can be tackled through careful design and simulation.

Temperature's Role

3. Fighting the Heat

Heat is the enemy! Leakage current is strongly temperature-dependent. As the temperature increases, the leakage current tends to increase exponentially. This is because higher temperatures provide more thermal energy, which allows more electrons to overcome the energy barrier and leak through the MOSFET. It's like trying to hold back a crowd with a flimsy barrier; the hotter things get, the easier it is for people to push through.

So, what can you do? Efficient heat sinking is crucial. Make sure your MOSFET has adequate thermal management to dissipate heat effectively. This could involve using heat sinks, fans, or even liquid cooling in extreme cases. Think of it like giving your MOSFET a nice, cool bath to keep it happy.

Another approach is to use circuit design techniques that minimize power dissipation. This will reduce the amount of heat generated in the first place. For example, using lower supply voltages or optimizing switching frequencies can help to reduce power consumption and keep the MOSFET cooler. It is very helpful if you use a PWM technique for the MOSFET.

In summary, keeping your MOSFET cool is essential for minimizing leakage. By using effective heat sinking and minimizing power dissipation, you can keep the temperature down and reduce leakage currents. It's a simple but often overlooked aspect of MOSFET design.

THE MOS DEVICE. Ppt Download

Circuit Design Tricks

4. Smarter Circuitry for Lower Leakage

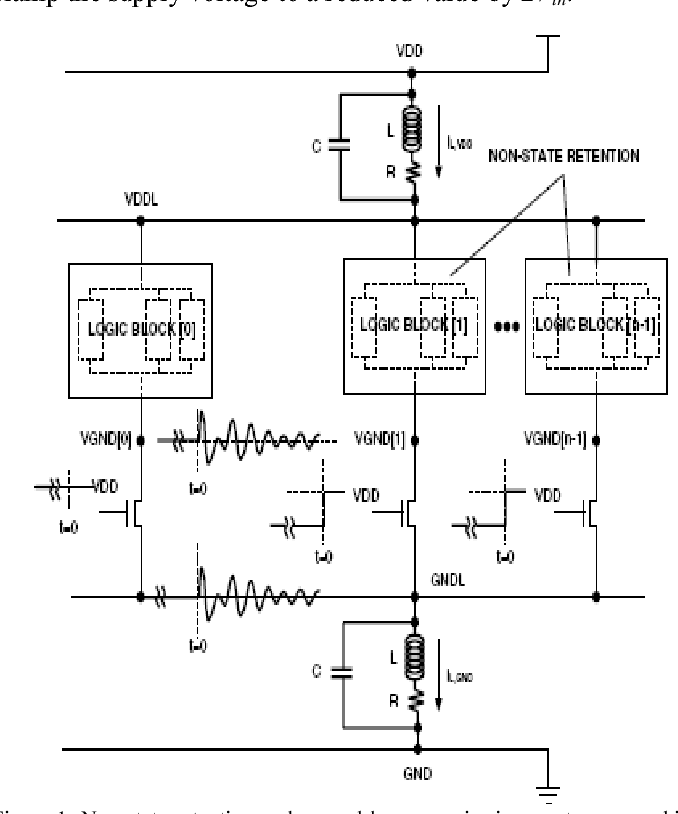

Beyond the MOSFET itself, smart circuit design can also help to reduce leakage. One technique is to use power gating. This involves completely cutting off the power supply to a circuit block when it's not in use. It's like turning off the lights in a room when you leave; it prevents any current from flowing and eliminates leakage entirely.

Another approach is to use dynamic voltage and frequency scaling (DVFS). This involves adjusting the supply voltage and clock frequency of a circuit based on its current workload. When the circuit is idle, the voltage and frequency can be reduced, which reduces power consumption and leakage. It's like putting your car in eco-mode to save gas.

You can also use sleep transistors. These are MOSFETs that are specifically designed to have very low leakage currents. They can be used to isolate parts of the circuit when they are not needed, preventing leakage current from flowing into those sections. It's kind of like having a special door that seals tightly to prevent drafts.

Furthermore, consider using a diode. Adding a diode in series with the MOSFET's gate can help to reduce gate leakage current. The diode acts as a one-way valve, preventing current from flowing backwards into the gate. This can be particularly useful in applications where the gate voltage might experience transients or spikes.

Choosing the Right MOSFET

5. Picking the Perfect Part

The easiest solution is often selecting a MOSFET that is known for its low leakage characteristics. Different MOSFETs have different leakage specifications, so carefully reviewing the datasheet is crucial. Look for MOSFETs that are specifically designed for low-power applications, as they often have lower leakage currents.

Pay attention to the drain-source leakage current (IDSS) and the gate leakage current (IGSS) specifications. These parameters indicate the amount of current that will leak through the MOSFET when it's in the off state. Lower values are better, of course!

Beyond the datasheet, consider the specific requirements of your application. If you need very low leakage, you might be willing to sacrifice some switching speed or on-resistance. Conversely, if you need high performance, you might have to tolerate slightly higher leakage. It's all about finding the right trade-off for your needs.

Choosing the right MOSFET is like choosing the right tool for the job. Select one that is well-suited for your specific application and has the low leakage characteristics that you need. Taking the time to do your research and select the right MOSFET can save you a lot of headaches down the road.

Figure 1 From Analytical Investigation Of GatetoDrain Leakage Current

FAQ

6. Your Burning Questions Answered

Let's face it, dealing with MOSFET leakage can be confusing. Here are a few frequently asked questions to help you out:

Q: What happens if I ignore MOSFET leakage?

A: Ignoring leakage can lead to shorter battery life in portable devices, increased power consumption, overheating, and even circuit malfunction. Think of it like ignoring a small leak in your roof; it might not seem like a big deal at first, but it can eventually lead to serious damage.

Q: Can I completely eliminate MOSFET leakage?

A: In practice, it's almost impossible to completely eliminate leakage. However, by using the techniques discussed in this article, you can significantly reduce it to acceptable levels.

Q: How often should I check for MOSFET leakage?

A: It depends on the application. For critical applications, regular testing is recommended. For less critical applications, periodic checks might be sufficient. It's like checking the oil in your car; you don't need to do it every day, but you should do it regularly.

Q: Does the type of load connected to the MOSFET affect leakage?

A: Yes, capacitive loads can increase the impact of leakage. Even small leakage currents can slowly charge a capacitor, potentially leading to unexpected behavior or increased power consumption over time. This is especially important to consider in low-power, battery-operated applications.