Here Is A Quick Way To Solve A Tips About What Is BOM Requirements

Unpacking the Mystery of BOM Requirements

1. What's the Big Deal About BOMs?

Okay, let's talk about BOMs. No, not those explosive things you see in action movies! In the world of manufacturing and product development, a BOM stands for Bill of Materials. Think of it as a detailed recipe for your product. If you're building a chair, the BOM lists every single leg, screw, seat, and paint needed to bring that chair to life. It's a comprehensive list that leaves no room for guesswork, which is incredibly useful for efficient production.

Imagine trying to bake a cake without a recipe. You might get close, but you'll probably end up with a lopsided disaster that tastes vaguely of disappointment. A BOM prevents that disaster in manufacturing. It ensures everyone involved — from procurement to assembly — knows exactly what's required, eliminating costly mistakes and delays. It's the backbone of a well-oiled production process.

So, where do "BOM requirements" come into play? Well, every company and every product might have slightly different needs for their BOM. For instance, a simple wooden toy might have a pretty straightforward BOM with a few parts. But a complex electronic gadget? That BOM could be hundreds or even thousands of lines long, specifying everything from microchips to specific types of solder. That's where understanding the specific "BOM requirements" for your project becomes essential.

In essence, understanding what is BOM requirements means understanding all the specific details and information your BOM needs to contain. It's about asking questions like: What level of detail is needed? Which specific attributes for each part are critical? How often will the BOM need updating? By answering these questions, you can create a BOM that truly serves its purpose and helps you build awesome products.

Materials Requirements Planning Manufacturing Resources Ppt

Diving Deeper

2. What Information Do BOMs Need, Exactly?

Alright, let's get a bit more specific. What kind of information typically goes into a BOM, and therefore, what kinds of things are considered "BOM requirements"? At its core, a BOM should contain at least the following: Part Number (a unique identifier for each component), Part Name (a descriptive name of the component), Quantity (how many of each part are needed), and Unit of Measure (whether you need 5 screws, 2 liters of paint, etc.).

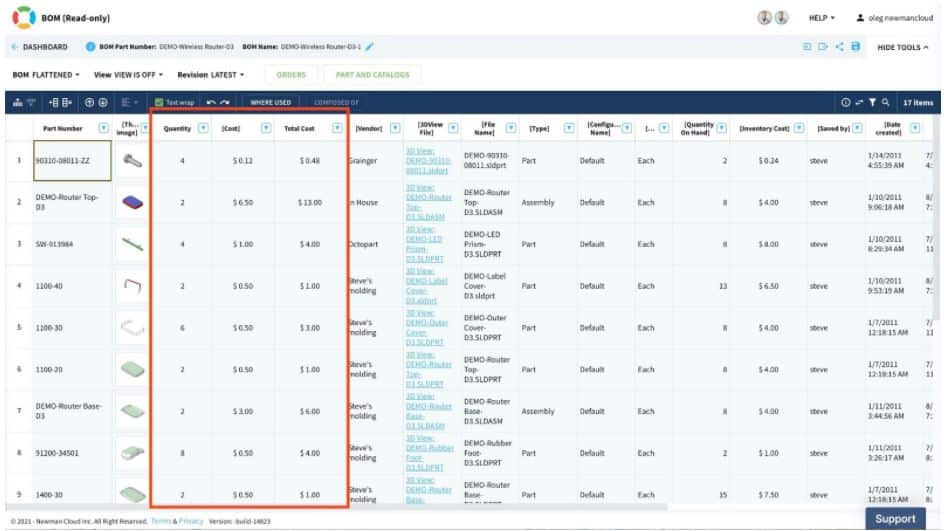

But those are just the basics! Depending on your industry and the complexity of your product, you might need to add a whole lot more. Think about things like material specifications (e.g., "stainless steel, grade 304"), vendor information (who supplies the part), cost, lead time (how long it takes to get the part), and even CAD drawings or specifications. The more detail you include, the clearer the picture is for everyone involved, and the less likely things are to go sideways.

Consider an example. If you're building a bicycle, your BOM requirement for the tires will include more than just "tire." You'll need to specify the tire size (e.g., 26"), the tire type (e.g., mountain bike tire), the material (e.g., rubber compound), and possibly even the specific brand and model number. This level of detail makes it crystal clear what needs to be ordered and assembled.

Also, its important to consider regulatory compliance requirements. If your product needs to meet certain safety standards or environmental regulations (like RoHS or REACH), you'll need to include information in your BOM to demonstrate compliance. This might involve specifying materials that are free of hazardous substances or including certifications that prove the part meets required standards.

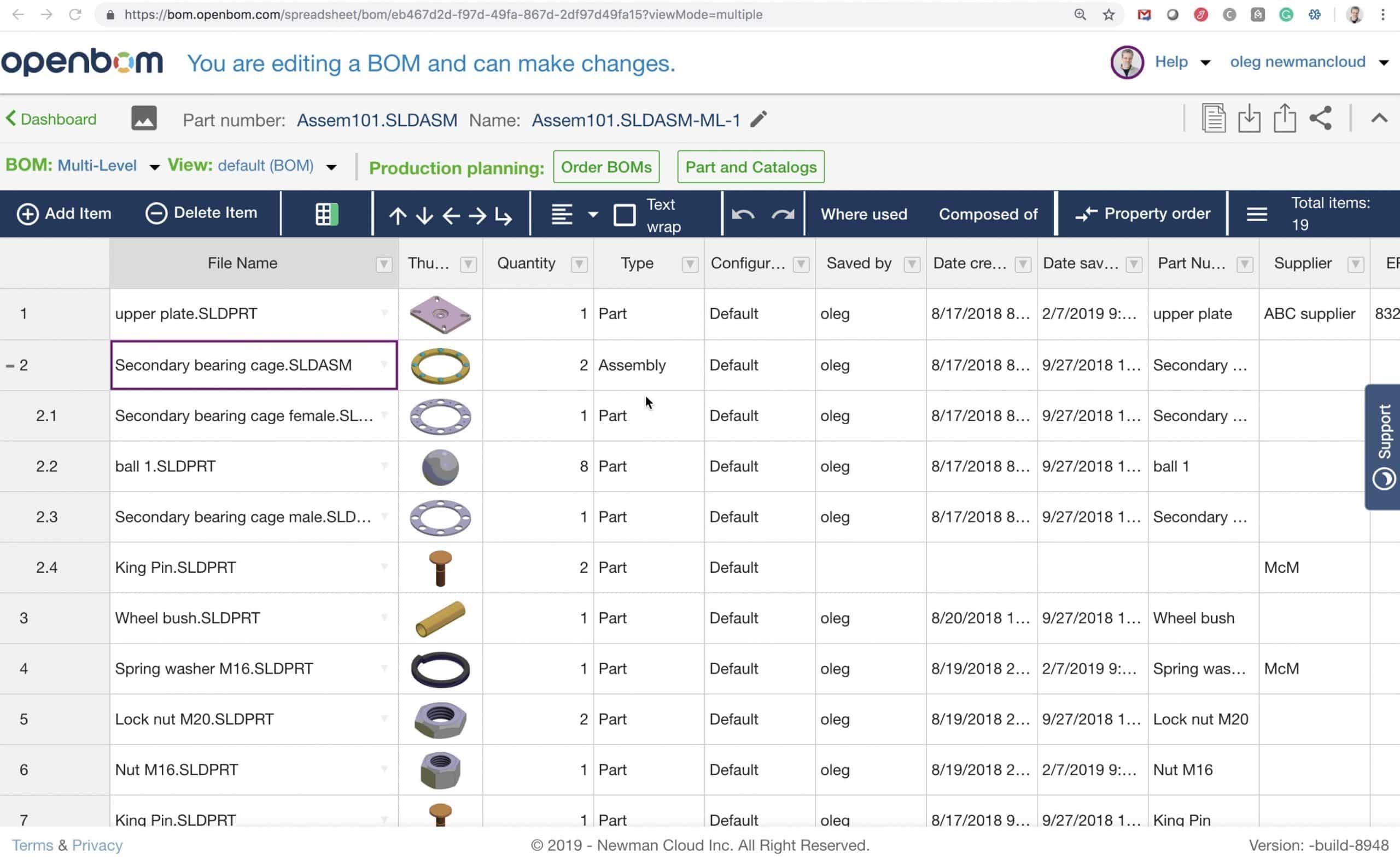

What Is A Bill Of Materials (BOM)? Example And Meaning, BOM Types OpenBOM

Types of BOMs

3. Engineering BOM vs. Manufacturing BOM

Did you know there are different types of BOMs? It's true! The two main types are the Engineering Bill of Materials (EBOM) and the Manufacturing Bill of Materials (MBOM). The EBOM focuses on the design and engineering aspects of the product, while the MBOM is all about how the product is actually built on the factory floor. Understanding the difference is vital because each has different "BOM requirements."

The EBOM is typically created by engineers and includes all the components needed to define the product's functionality and performance. It might include parts that aren't physically part of the final product, like test fixtures or special tools used during development. Its "BOM requirements" are heavy on technical specifications and design parameters.

On the other hand, the MBOM is tailored for manufacturing and focuses on the parts and processes needed to assemble the product efficiently. It often includes details like assembly steps, tooling requirements, and work instructions. Its "BOM requirements" emphasize manufacturability and practical considerations for the production line.

So, which one do you need? Well, often you need both! The EBOM serves as the starting point, and the MBOM builds upon it, adding the specific details needed for production. Effective communication between engineering and manufacturing is key to ensuring both BOMs are accurate and aligned, leading to a smoother and more efficient product development process.

10 Types Of BOM And Why They Matter?

Making it Work

4. Tips for a Smooth BOM Process

Okay, so you know what a BOM is and what kind of information it should contain. But how do you actually manage it effectively? Here are a few best practices to ensure your BOM process is smooth, accurate, and, dare I say, even enjoyable.

First, centralize your BOM data. Ditch the spreadsheets scattered across different computers and invest in a dedicated BOM management system (often part of a larger PLM — Product Lifecycle Management — system). This ensures everyone is working from the same, up-to-date information, preventing costly errors and version control nightmares. These systems allow controlled access, audit trails, and facilitate revision management.

Second, embrace change management. Products evolve, designs get updated, and components become obsolete. Your BOM needs to reflect these changes accurately and efficiently. Implement a robust change management process to track revisions, approvals, and the impact of changes on the BOM. The key BOM requirement is to control and capture these changes for future and present reference. This will eliminate errors in production and purchasing.

Third, encourage collaboration. A BOM is not a solo project. It requires input from engineers, procurement, manufacturing, and even sales and marketing. Foster a collaborative environment where everyone can contribute their expertise and ensure the BOM accurately reflects the product's requirements from all angles. Regular meetings to review the BOM can be really helpful.

Finally, automate as much as possible. Manual data entry is a recipe for errors. Integrate your BOM management system with your CAD software, ERP system, and other business applications to automate data transfer and reduce the risk of mistakes. This frees up your team to focus on more strategic tasks, like improving product design and optimizing the manufacturing process. Plus, it saves valuable time and resources.

BOM Requirements And Purchase Calculations YouTube

Common Pitfalls and How to Avoid Them

5. Steering Clear of BOM Disasters

Even with the best intentions, BOMs can sometimes go wrong. Here are a few common pitfalls to watch out for, along with tips on how to avoid them. One common error is using inconsistent part numbers. This can happen when different departments use different naming conventions, leading to confusion and ordering the wrong parts. Establish a clear and consistent part numbering system across the entire organization and enforce it rigorously. This is a critical "BOM requirement" for preventing chaos.

Another pitfall is failing to update the BOM when changes are made to the product design. This can lead to manufacturing using outdated information and building the product incorrectly. Implement a formal change management process to ensure all changes are properly documented and reflected in the BOM. This process should involve clear communication and approval workflows to prevent errors. The "BOM requirement" here is robust revision control.

Insufficient detail is another frequent problem. A vague BOM entry like "screw" isn't very helpful. Specify the screw type, size, material, and any other relevant attributes to avoid ambiguity. Remember, the more detail, the better. This falls directly under BOM requirements. A good question to ask is, "Is there enough detail so that anyone could understand what this part is without asking questions?".

Lastly, neglecting to consider supplier lead times can cause major delays. If a critical component has a long lead time, it needs to be factored into the production schedule. Include lead time information in the BOM and monitor it closely to avoid stockouts and production bottlenecks. Consider BOM requirements to align with inventory management and lead times of parts.

What Is A Bill Of Materials (BOM)? TRANQUIL

FAQ

6. Demystifying BOMs, One Question at a Time

Let's tackle some frequently asked questions about BOMs to clear up any remaining confusion.

Q: What's the difference between a single-level BOM and a multi-level BOM?

A: A single-level BOM shows only the components directly used to assemble the finished product. A multi-level BOM, on the other hand, breaks down the product into sub-assemblies and shows the components needed for each sub-assembly. Multi-level BOMs are useful for complex products with many layers of components.

Q: How often should I update my BOM?

A: The BOM should be updated whenever there is a change to the product design, materials, or manufacturing process. It's best to have a formal change management process in place to ensure changes are captured and reflected in the BOM promptly.

Q: What are the benefits of using a BOM management system?

A: A BOM management system centralizes BOM data, improves accuracy, streamlines change management, enhances collaboration, and automates data transfer, leading to more efficient product development and manufacturing processes. They can drastically reduce errors in production.

Q: Is "BOM requirements" always about the technical stuff?

A: Not always! While technical specifications are crucial, "BOM requirements" can also include things like regulatory compliance, cost considerations, supplier agreements, and even marketing requirements (e.g., packaging materials). It is vital to align these requirements with the business and technical needs.